ATS Super Silent LSD technical information

*Silent technology on the clutch platesThe current ATS LSD clutch plates are assembled into an LSD without grinding the surface right after heat treatment. This non grinded plate with a “moderately coarse surface” is believed to be the most effective with its ideal frictional characteristics and with its unbeatable durability. However, from the stand point of noise level, it has a room for improvement.

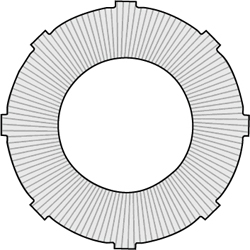

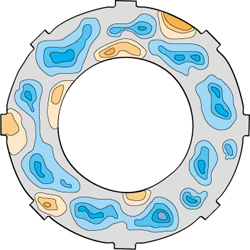

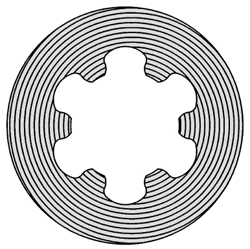

There are several uneven areas of between 0.003 to 0.01 mm on the surface of the non- grinded plate as shown by a contour line on the diagram below. This irregular unevenness, can rub against each other producing a strong friction force which is ideal for a performance LSD but at the same time can cause some unwanted noise. In order to compensate for the noise and also to assure the smooth lubrication, the ATS LSD metal plates have many grooves in a “radial” manner on the plates with outer tabs and multiple grooves in a concentric circle manner on the plates with inner tabs.

From the extensive research on the reduction of the noise, ATS has learned that any chemical treatment or shot peening process (like WPC) on the uneven plate surface does not last very long. ATS also learned that grinding off the surface entirely causes insufficient lubrication of the surface and results in burning the plate or in early wear deterioration.

The challenge was to find a way to grind a plate for noise reduction without negatively impacting the oil circulation. First, ATS focused upon the oil movement itself within an LSD case. LSD oil, which has influence on the performance of an LSD, always circulates from the center to the outer side due to the centrifugal force. Then, from the simulation of the oil movement, ATS found that a combination of the current design of the concentric circle grooves and the ground plates reduces the noise significantly without negatively impacting lubrication. The clutch plates with outer tabs for the Super Silent LSD is ground to remove the unevenness and at the same time the radial grooves are eliminated to maintain sufficient oil on the friction surface. The grooves on the plates with the inner tabs are designed in concentric circle manner with the center of the concentric circle slightly shifted from the actual center of the plate. The grooves lubricate both plates (one with outer tabs & one with inner tabs) without oil starvation.

The results are:

Merit 1: The plate surface becomes very even. Localized pressure areas which were one of the causes of the unwanted chattering noise are significantly reduced.

Merit 2: The removal of the radial grooves on the plate with outer tabs keeps sufficient oil on the surface and reduces metal friction noise.

Merit 3: The concentric grooves on the plate with inner tabs assure smooth oil circulation from the center to outer side achieving the most effective lubrication.

| The current plate with outer tabs – non-grinded plate with radial grooves | The irregular unevenness shown by a contour line on the current plate |

|

|

The plates used for the ATS Super Silent LSD |

|

|

|

| A Super Silent LSD plate with inner tabs. Non-grinded plate with grooves in a concentric manner. | A Super Silent LSD plate with outer tabs. The plate is grounded after heat treatment and the grooves are then eliminated. |

*Silent technology on cam angle

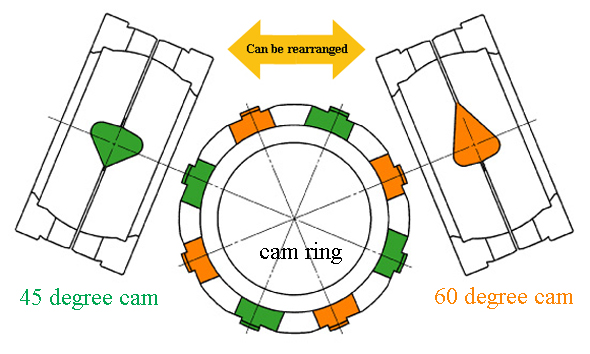

The initial torque (break away torque) and the cam angle on the cam rings determine the responsiveness of the LSD on the driver’s steering and throttle inputs. The standard ATS Metal LSD’s, designed for competitions, are equipped with 55 to 65 degrees cam angles. Those cam angles assure a very rapid and effective differential lock at racing speeds. However, the steep angles do not always provide a smooth ride on street driving and ATS concludes there is room to change the cam angle for a more quiet operation without sacrificing the effectiveness in most driving situations.

The ATS Super Silent LSD comes with a cam ring with both 45 degree and 60 degree (or 55 degree in the case of 87mm & 82 mm diameter plates) cam angles. At the factory (if it is not specified at the time of an order), the cam angle is set at 45 degree for the most silent operation with a slight retarded responsiveness. The 45 degree cam angle provides extremely smooth street driving without any “jerky” movements. But when the driver desires a higher responsiveness, it can be easily changed to the 60 degree cam angle.

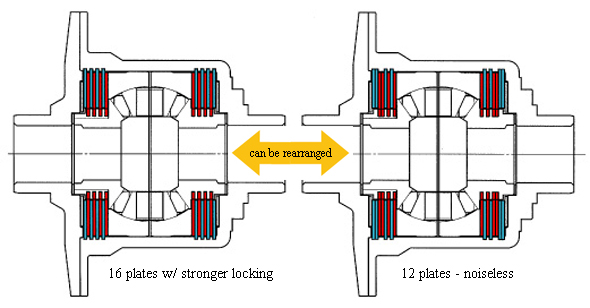

* Silent technology on the number of the clutch plates

The newly designed clutch plates for the Super Silent LSD ensures the differential lock is at a superbly modulated level. There are either 16 or 20 newly designed plates in the Super Silent LSD. For a Super Silent LSD to remain absolutely silent under any driving condition, ATS found that the number of the internal plates has to be 12. By rearranging the order of the plates, the Super Silent LSD is assembled with 12 plates if it is not specified at the ordering. As in the case of cam angle, this can be converted to 16 easily by rearranging the plates if a drivers wishes to do so. By effectively reducing the number of the internal plates to 12, the Super Silent LSD guarantees a noiseless operation even for a car with a very small turning radius like Mazda Miata.