ATS Triple Carbon Clutch [ Standard / Spec II ]

This excellent performance clutch is intended for extreme powers as high as 1,200 hp (at the wheel). At the same time, we made half clutch operation even easier to control than it is for the carbon single/twin clutch. There is absolutely no need to worry about poor disengagement. The carbon disk weighs 210g and inertia weight is kept at a minimum, so that gear shifting is as quick as it is with a regular clutch. This is the ultimate clutch that is much longer-lasting than metal clutches, astonishingly strong because of our non-mesh random-weaving method, and will not be damaged by repeated severe driving.

With the introduction of Spec II, ATS successfully made the pedal effort lighter than stock (w/ 1,400kg clamping force) which has enhanced your driving comfort and pleasure immensely.

With the introduction of Spec II, ATS successfully made the pedal effort lighter than stock (w/ 1,400kg clamping force) which has enhanced your driving comfort and pleasure immensely.

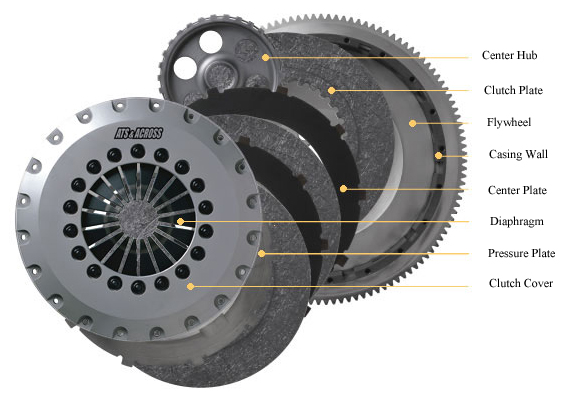

Center Hub

Thanks to its superior properties, our damper-less carbon disk has shock-absorbing capability that is ten times higher than that of a disk with a damper. Because weight reduction is desirable in a center hub, ours has the most lightweight damper-less design. It consists of a main body composed of a carburized chrome-molybdenum material and an ultra-thin piano wire to anchor the disk.

Thanks to its superior properties, our damper-less carbon disk has shock-absorbing capability that is ten times higher than that of a disk with a damper. Because weight reduction is desirable in a center hub, ours has the most lightweight damper-less design. It consists of a main body composed of a carburized chrome-molybdenum material and an ultra-thin piano wire to anchor the disk.

Clutch plate

Made of a unique friction material developed by ATS & ACROSS. The enormous strength created by our non-mesh random-weaving method will prevent damage during driving. The ultra light carbon disk changes controllability and acceleration characteristics. The clutch has excellent friction characteristics even when cold so that it is always free of slippage at full acceleration and feels strong and stable. It also provides very smooth engagement.

Made of a unique friction material developed by ATS & ACROSS. The enormous strength created by our non-mesh random-weaving method will prevent damage during driving. The ultra light carbon disk changes controllability and acceleration characteristics. The clutch has excellent friction characteristics even when cold so that it is always free of slippage at full acceleration and feels strong and stable. It also provides very smooth engagement.

Flywheel

To attain high precision, we use our unique large-scale dedicated machining process capable of performing all fabrication processes (from lathe turning to gear tapping) in one chucking. This makes excellent dynamic balance possible. Optimal weight is determined based on the vehicle type and usage. In combination with its highly rigid cover, our flywheel is very resistant to distortion.

To attain high precision, we use our unique large-scale dedicated machining process capable of performing all fabrication processes (from lathe turning to gear tapping) in one chucking. This makes excellent dynamic balance possible. Optimal weight is determined based on the vehicle type and usage. In combination with its highly rigid cover, our flywheel is very resistant to distortion.

Casing

Our clutch uses a carbon disk with a diameter of 230mm, while its external size is kept equivalent to our competitor's products. This is made possible by minimizing the thickness of the casing without sacrificing the required strength.. For weight reduction and carbon dust removal, the side of the casing has holes around its entire circumference. This casing anchored to the cover and flywheel with 40 bolts. This design maximizes the rigidity of the clutch and supports heat-resistance and stable operation.

Our clutch uses a carbon disk with a diameter of 230mm, while its external size is kept equivalent to our competitor's products. This is made possible by minimizing the thickness of the casing without sacrificing the required strength.. For weight reduction and carbon dust removal, the side of the casing has holes around its entire circumference. This casing anchored to the cover and flywheel with 40 bolts. This design maximizes the rigidity of the clutch and supports heat-resistance and stable operation.

Center Plate

The optimal amount of mass inhibits thermal distortion, and the carbon treatment improves characteristics during the initial break-in period. This reduces initial abrasion and stabilizes performance at half clutch.

The center plates are totally re-designed for the Spec II for increasing the durability of the clutch with the high leverage ratio.

The optimal amount of mass inhibits thermal distortion, and the carbon treatment improves characteristics during the initial break-in period. This reduces initial abrasion and stabilizes performance at half clutch.

The center plates are totally re-designed for the Spec II for increasing the durability of the clutch with the high leverage ratio.

Diaphragm

The diaphragm is carefully designed to prevent cracks caused by concentration of stress and fatigue-induced damage from repeated clutch operation. Together with the pressure plate at its optimally-determined size, the diaphragm provides ideal clamping power and work strokes.

The Spec II is available in single diaphragm spring for a lighter-than-stock pedal effort.

The diaphragm is carefully designed to prevent cracks caused by concentration of stress and fatigue-induced damage from repeated clutch operation. Together with the pressure plate at its optimally-determined size, the diaphragm provides ideal clamping power and work strokes.

The Spec II is available in single diaphragm spring for a lighter-than-stock pedal effort.

Pressure Plate

By using the valuable feedback data from repeated road tests, we have created a pressure plate that takes full advantage of our friction material properties. The light pedal feel and the clamping force suitable for a carbon clutch are achieved together.

The pressure plate is totally re-designed for Spec II for a higher leverage ratio.

By using the valuable feedback data from repeated road tests, we have created a pressure plate that takes full advantage of our friction material properties. The light pedal feel and the clamping force suitable for a carbon clutch are achieved together.

The pressure plate is totally re-designed for Spec II for a higher leverage ratio.

Clutch Cover

Our clutch cover has greater rigidity established by aluminum forging and shot peening. The cover houses a carbon disk that has the world's largest diameter of 230mm. At the same time, the external size of the clutch is kept equivalent to our competitor's products. As many as 20 bolts secure the whole structure, which increases the rigidity and the rotation precision of the entire clutch.

Our clutch cover has greater rigidity established by aluminum forging and shot peening. The cover houses a carbon disk that has the world's largest diameter of 230mm. At the same time, the external size of the clutch is kept equivalent to our competitor's products. As many as 20 bolts secure the whole structure, which increases the rigidity and the rotation precision of the entire clutch.